Narrative of Renaissance formation in pasta industry

- news

- Narrative of Renaissance formation in pasta industry

Narrative of Renaissance formation in pasta industry

- مدیر سایت

- October 7, 2023

- 4:59 pm

- No Comments

Morteza Meysami Fard, founder of Tak Macaron Company and current manager of Taknan Jonoob Company, was born in January 1942 in the middle of World War II in Ahvaz, Iran. His father and his father’s relatives, who were originally Esfahani, moved to Ahvaz, and all were engaged in cereal trade, and some time later, they entered into agricultural activities. He completed his education to diploma level in Isfahan and returned to Ahvaz in 1962 with the death of his father again and began working and working. He said, “The Green Economy” continues with this famous pasta producer.

Tell us about your start in the food industry.

After completing my military training, I participated in the field of “business management” with an intrinsic interest in business and managed to accept this field. I completed my studies in Tehran in 1969 and then returned to Ahvaz to work in this field with the cooperation of my brothers who had just obtained the license to build flour mill. In 1969 I founded the flour factory of the south. We did.

In 1972, with my constant interest in pasta production and by observing the traditional pasta factories that supplied their flour from us, I thought about producing pasta, but with the start of the Islamic Revolution and several years after the country was involved in the imposed war, it was not possible to achieve this goal.

Involved in the issues of war and the subsequent migration of most people from Khuzestan, most of my acquaintances told me why you were not leaving Ahvaz, and I replied to them, “This is my home and my life,” so we kept our trenches and the factory did not stop, even our electrical installations were attacked by the enemy, but it was restored by the support forces.

With the end of the war, we decided to develop the flour mill south, our factory was among the third to bring a German factory into the Iranian business. Of course, at that time, the Swiss factory “Bouler” was operating in Iran, but the market was not that large, because the Swiss are generally dry people and, like the Germans, were not successful businessmen in making connections.

How did the Tak Macaron factory start its work?

In 1993, with a long time interest in the construction of pasta production plant, I bought a piece of land in Ahvaz and subsequently obtained the necessary licenses. In fact, all conditions were ready to do this idea until I traveled to Tehran, where I met the engineer “Kermanshahi” who was the CEO of Bollar at the time, and told him that he was going to build a pasta factory. I have a production capacity of half a ton per hour, they told me, half a ton, which is very low, if you intend to do this at least one ton, I said I do not have the cost of this amount and it requires a lot of capital, Mr. Kermanshahi suggested that I do this instead of Ahvaz in Tehran and work in partnership with Mr. Kermanian and him, with the knowledge that has been going on since before Mr. “Mr.” I had a good job and I was sure it was a good one، so I decided to do it.

We met and agreed. Of course, Mr. Sadeghian was added to our collection at the suggestion of Mr. Kermanian and the ground for the construction of “Tak Macaron” in partnership with “Haj Mirza Hassan Sadeghiyan”, “Haj Abdolhossein Kermanian”, “Moqtada Kermanshahi” and “Bandar” in 1993 and with the aristocracy that I had gained over the years of studying and observing in person from pasta factories abroad and inside the country As the CEO of this complex (tak macaron) I started working in this field.

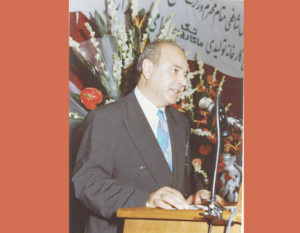

Initially, by purchasing 5 hectares of land at the site of the current “Tak Macaron” factory and buying the flour we needed, on October 17, 1998 the opening ceremony of the “Tak Macaron” factory was held, which coincided with the beginning of Mr. Khatami’s presidency. Of course, long before this date, pasta production was made by the company, but the official ceremony was held on this date. Until then, there were other factories in the field of pasta production that offered their products in the form of workshops, but the production method of “tak macaron” which was the production of “Continios” was only reserved for this group, in fact, “Tak Macaron” had the first production line of pasta with the method of “Continios” without interference from the beginning to the end, which is a long line of spaghetti production and a short line producing Fermi pasta.

What was the development process of Techmacaron Company and what were the problems?

With the start of the “Tak Macaron” activities, the plant in the early years prevented the export of $15 million, foreign currency. At first, the problem was how to act in pricing, on arrival there were two guests in the arena, traditional factories that sold pasta for a package of 45 tomans and another imported noodle of Ankara Turkey that sold 500 grams of pasta for 55 tomans. At the beginning we decided to deliver 500 grams of pasta at a price of 50 tomans to the consumer. Fortunately, we had good progress and our business department had good and timely advertisements in television and urban billboards, at that time we had two or three billion tomans a year for advertising throughout the country; eventually we entered the market and upgraded two production lines to 4 lines and bought two more lines from Buller. In the meantime in 2002 we were able to produce flour with a currency of 300 tomans This amount of currency reached 900 Tomans at the end of Mr. Khatami’s presidency, it was actually in 2005 that this complex started producing flour by establishing the “flour industry” company. In fact, we were the first brand in the production of full automatic pasta, and after us it was “Zar Macaron” and “Mana” who bought the new production lines. Of course, Mana has more history in this industry. I continued my activities in Tak Macaron until 2011 and I decided to cut the cooperation following changes in the board of directors who were not aware of the issues of the food industry.

How did you decide to build a “Mono-Bread Factory”?

From 2009, I decided to build a factory in Ahvaz, which might have been better than the beginning of this company in Tehran. Because Tehran is the capital and has 20 million people and Ahvaz has a population of 4 million. By a simple account, it is clear that the benefits of this work in Tehran were much greater than in Ahvaz. The decision coincided with the presidency of Mr. Ahmadinejad, who gave a long speech about industrial breads during that time, which many were affected by his words went bankrupt, and few companies with financial and credit backing were able to survive in this direction and stay in the industry. Fortunately, today Taknan produces 1.5 tons of daily hourly which is a significant figure and in the year 93 Fully exploited in the field of flatbread production We reached the

5 famous companies in the world have consulted and our experts are educated from Germany and England. Today, 10 products are offered to consumers in the “single bread” product basket which includes flat and bulky breads.

You explain how to produce toast and how you decided to add this bread to the “tak bread” basket.

Toast is a group of bulky breads, the main brand of this bread in the country, belongs to “Three Breads” that produces this bread with a very high capacity, of course, in a center of 20 million people, of course, should be produced in greater quantity; the original bread produced in Germany and European countries, in the form of test, which has different forms and we added this bread to our productions. Of course, we are involved in the production of other breads such as gatta bread and bagels and… We have action. It was after the production of Lavash bread that we decided to produce toast, which was not a difficult task, especially for those who have experience in producing bread. Before this decision in 1986, Mohammad Forouzandeh, the head of Khuzestan governorate, offered me to produce machine bread at the meeting of the Flour and Bread Council, and this issue passed. In 1984 we went to Germany with Mr. Kermanshahi and went from a bread factory. We visited that had 5 lines in the production of bulky breads, and one of the German engineers there told me, “The life of wheat is two years, and when it is floured, it has a life of 3 months, and when it is made bread, it has 5 days of use date, but when it is made into dough, it will last for 5 minutes, if you can do it, enter the field.” I was scared there, but I was scared. It was kind of like I experienced it too.

What do you plan for the future?

Soon we are going to turn the bread production line from semi-automatic to automatic, and our production will be in pieces if the piece is 1 Kilio 3000 pieces per hour and if it is 500 grams it will be 1500 pieces per hour.

As someone who is the founder of a new style in pasta production, how do you plan to flourish the industry and the leap in production under the conditions of corona?

Unfortunately, in our country, there are no congruent organizational complexes at high and low levels; at the moment, the customs system is disconnected and order registration is not taking place, there is a lot of unplanned in our customs system and there are many irresponsible people at work; now the slogan of the leap of production and removing barriers to production, unfortunately there is no such thing in the subset of the departments, in principle, Sadr does not correspond with the following. Our customs are the most problematic of all and in this organization they throw stones all the time, whereas in German customs we send sex for 15 minutes. It’s not possible to succeed with this system, progress has a certain definition, but we don’t have a definition for it, I’m 80 years old now, but I’ve never been neglected.

In the production of capacity, it is the first word; the factory that must work 24 hours if it works 8 hours, all costs remain in place; now in the industry, a fundamental problem of capacity and another problem is the lack of the required machinery parts, and alongside these two problems with the systemization of customs activities, the situation has not gotten better but worse.

Photos related to the opening of Tak Macaron factory – October 1996